Quality

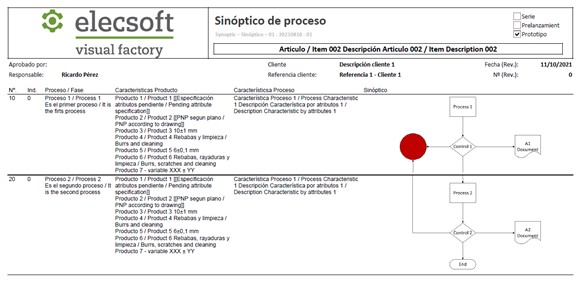

Visual Factory Quality: Project Management according to IATF 16949 (FMEA, Control Plan, Synoptic and Guidelines)

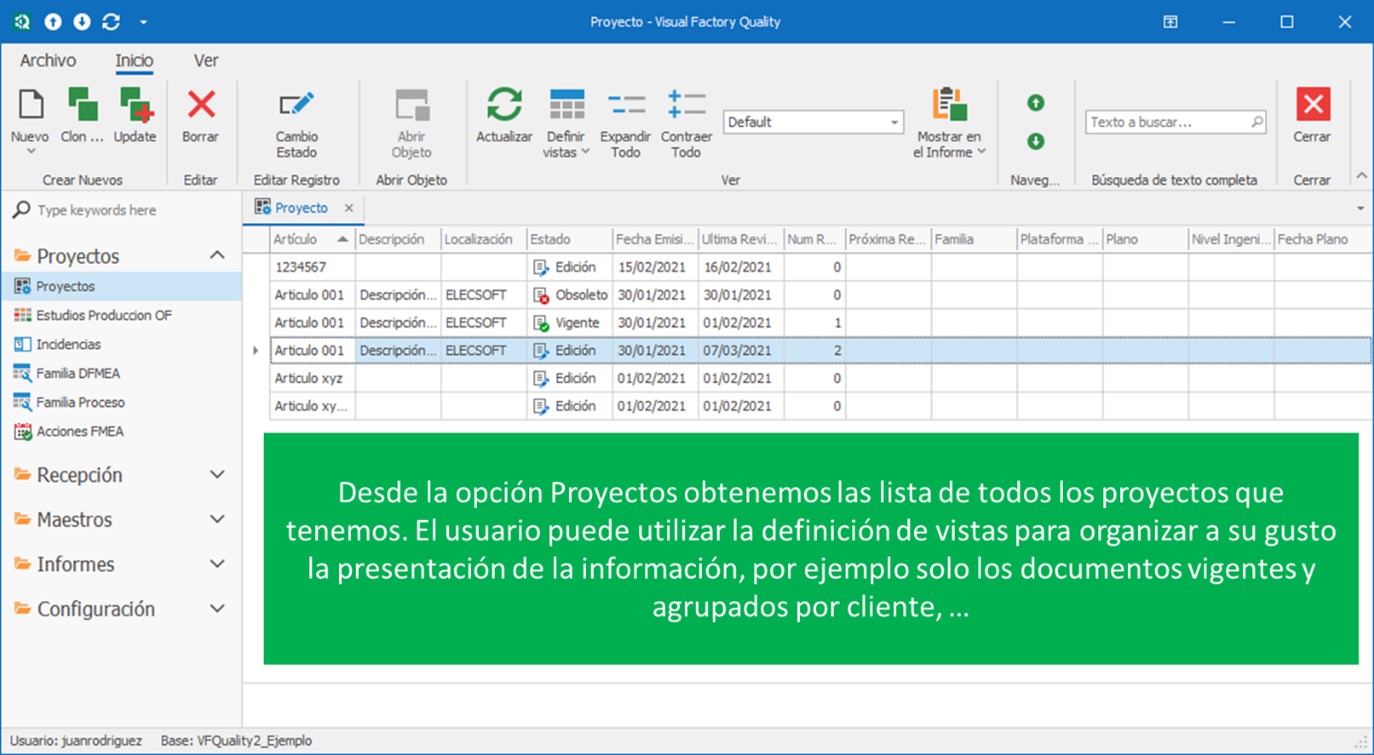

Visual Factory Quality is a software application designed to facilitate the monitoring of projects in companies in the automotive sector.

What does visual factory quality offer?

- Modular system. The client can acquire and activate those modules that are of interest to him.

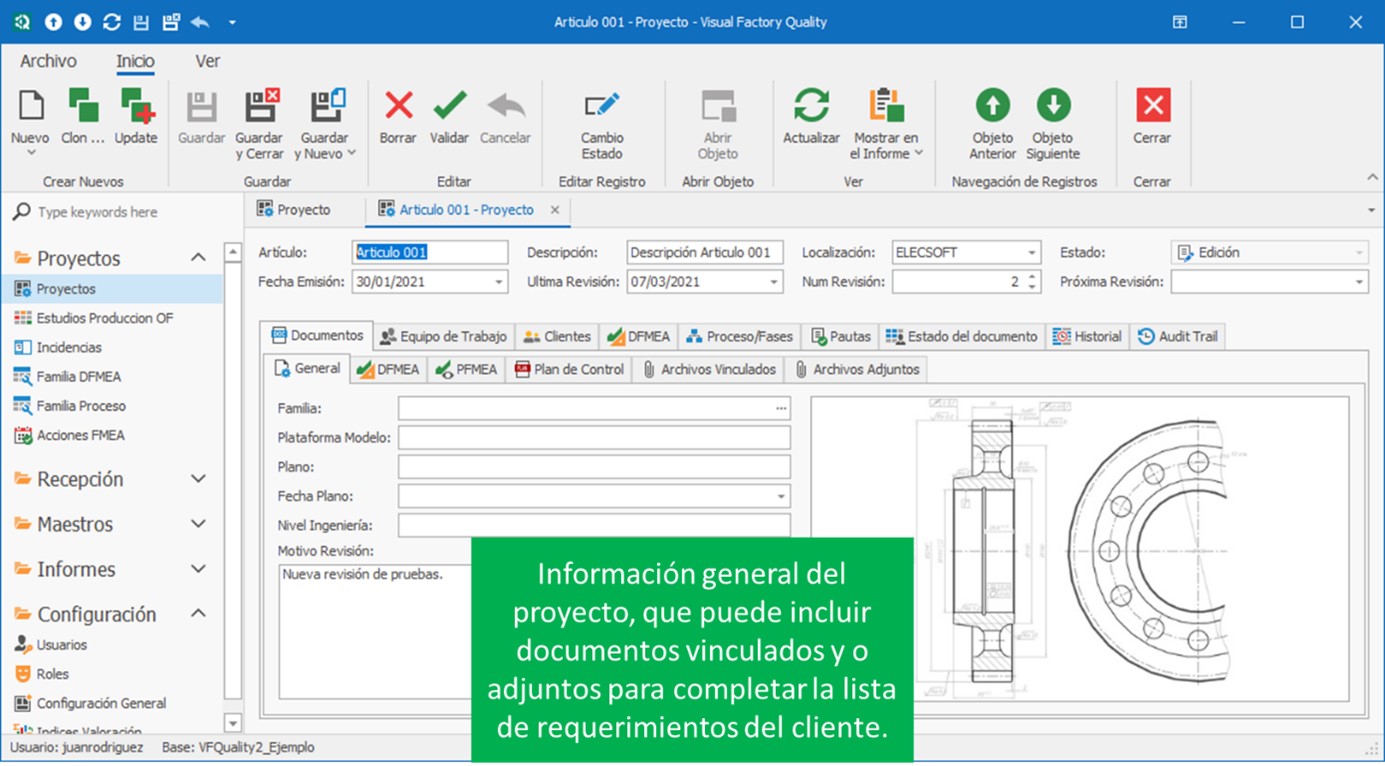

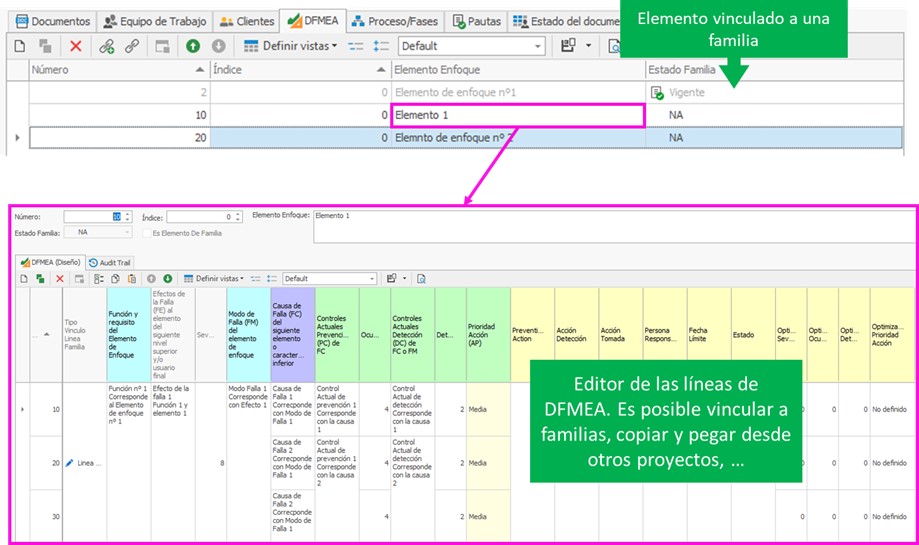

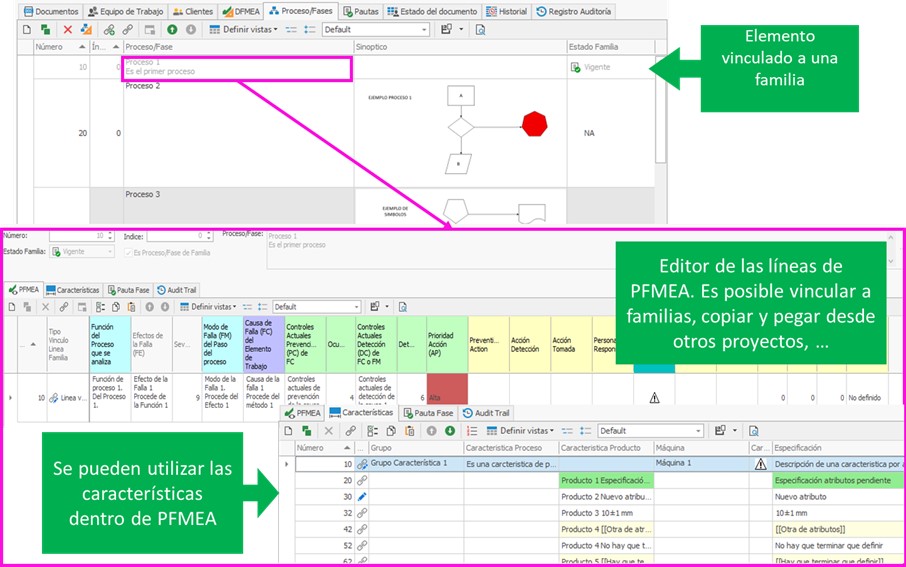

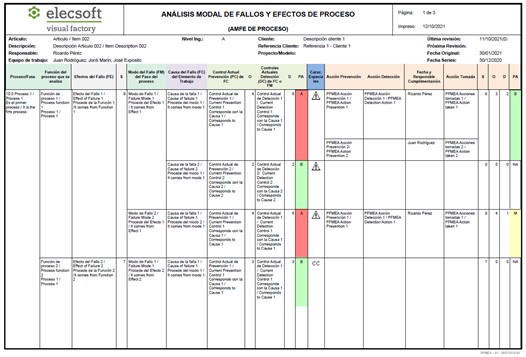

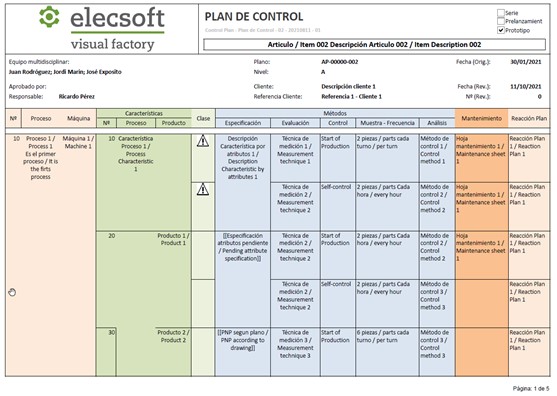

- Project management. Includes FMEA, Process Synopsis and Control Plan.

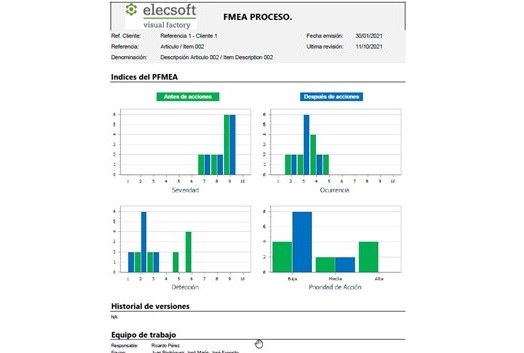

- New Priority of Action indexes according to AIAG and VDA referential.

- FMEA formats that comply with the new AIAG and VDA referential.

- Possibility of working with DFMEA, PFMEA, Control Plan and Synoptic Families to save time in the elaboration.

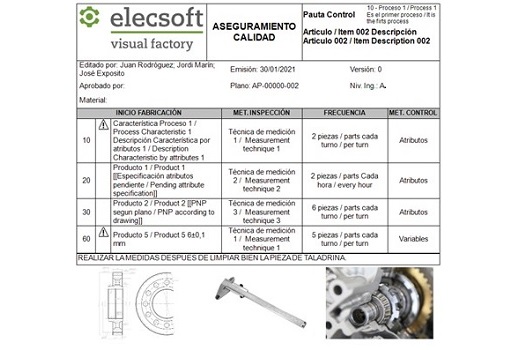

- Obtaining the different guidelines directly from the Control Plan.

- Link between the different modules and the company’s ERP system (optional).

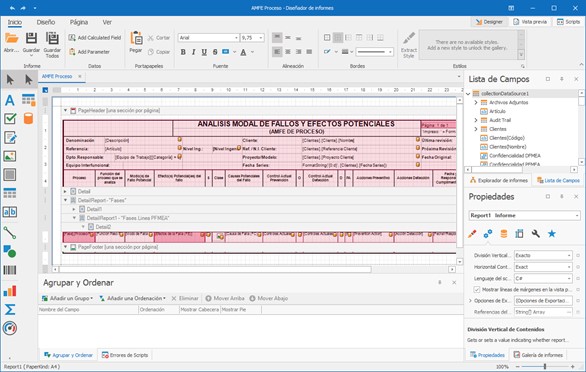

- Wide variety of views and reports, which can be expanded by the user.

- Audit Trail of the data entered.

- Electronic signature of the editing, revision and approval of documents.

- Review and approval statuses are configurable.

- Security integrated with Active Directory.

- Consultation of all information in real time.

- Complies with the current IATF 16949:2016 standard.

- Powerful view manager to present information according to the user’s needs.

- Integrated report designer.

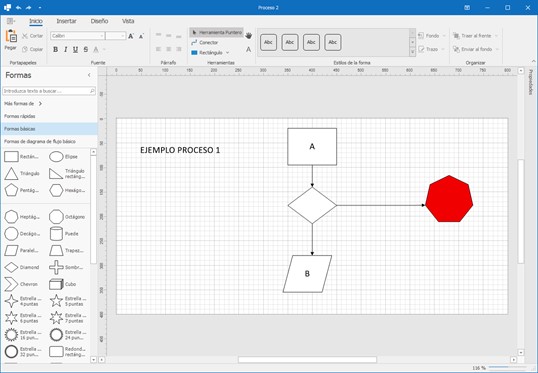

- Integrated diagram designer for Process Synoptic.

- Easy to configure and use.

- Supported by the technical support team

Visual Factory Quality is the application you need for Project Management.

Benefits of our project management software

Easy to install and use

References used