SPC

Visual Factory SPC: Leading software in Statistical Process Control and Capacity Analysis

With Visual Factory SPC perform real-time process and capacity statistical studies right at the machine

What does visual factory spc offer?

- Complete system for Statistical Process Control (SPC).

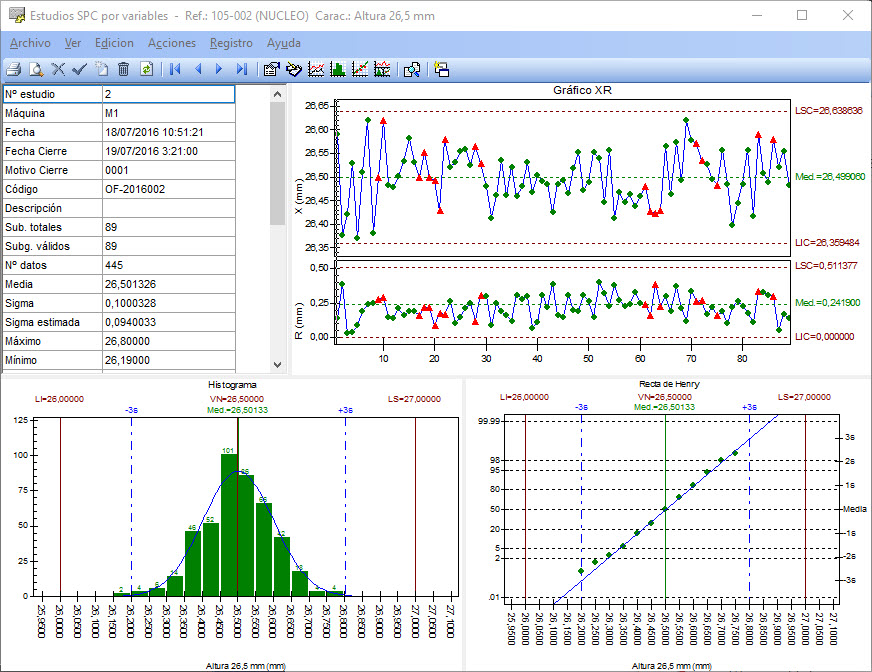

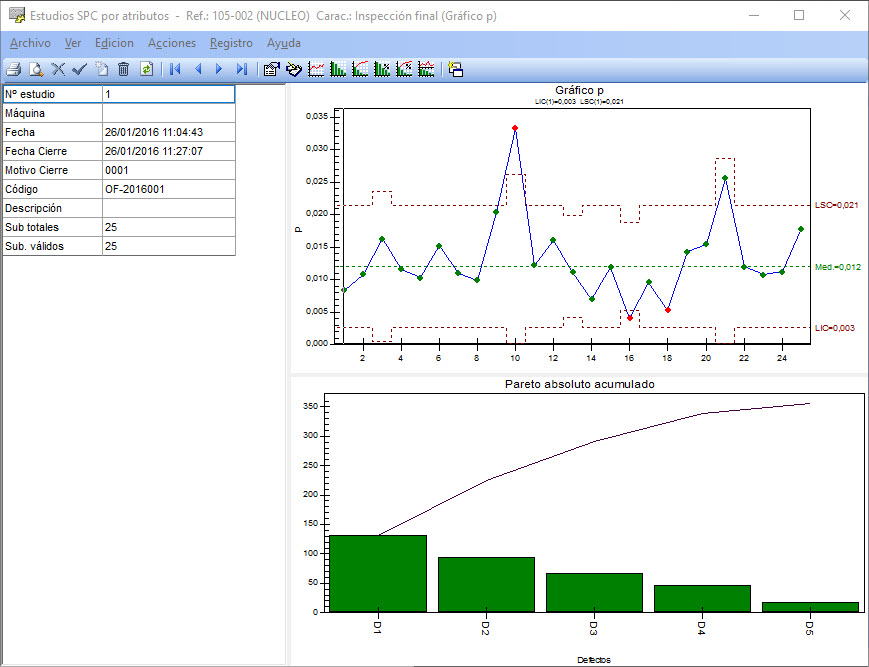

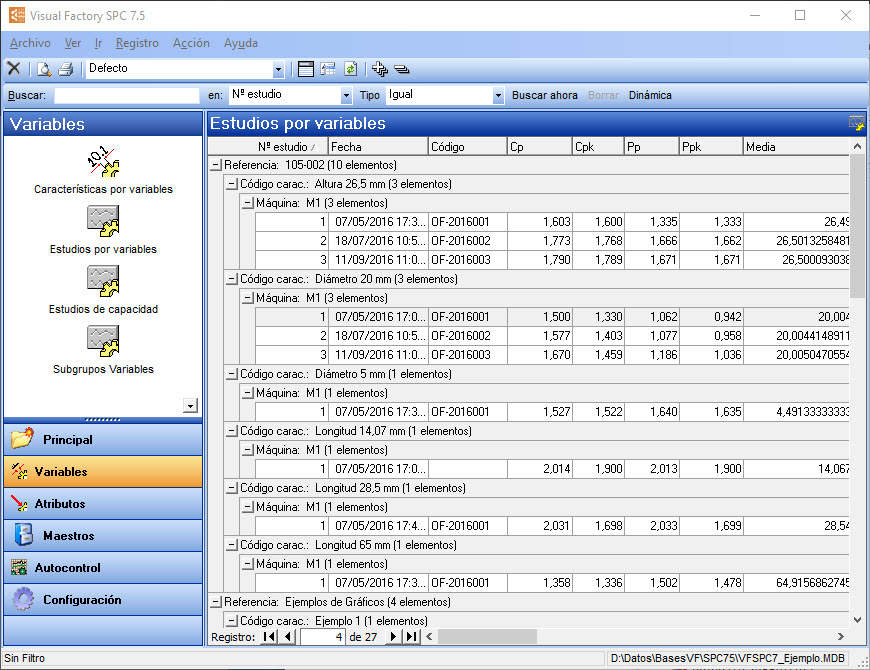

- Process studies by variables and by attributes.

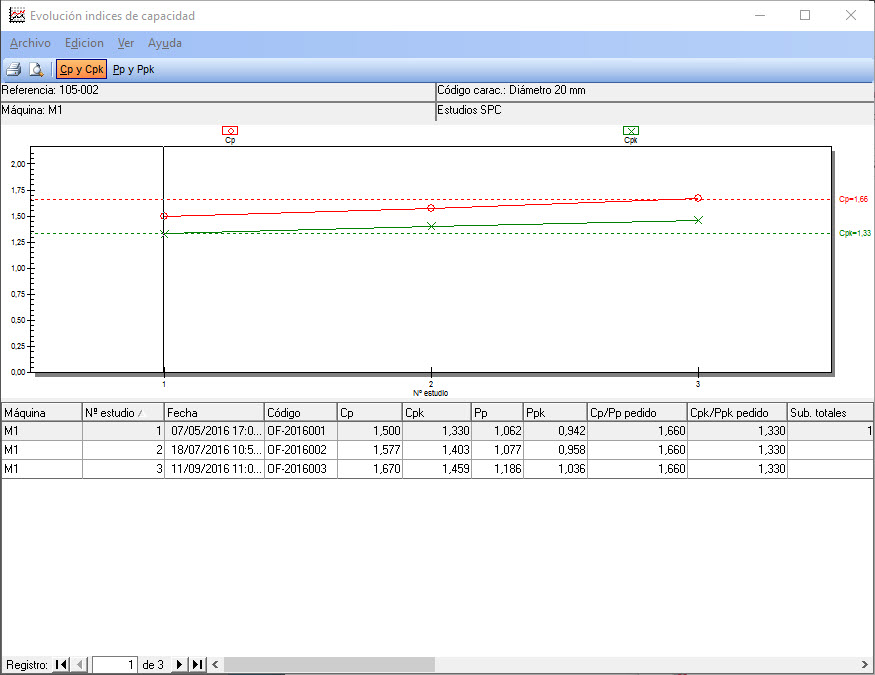

- Process and machine capacity studies.

- Calculations for Normal and Non-Normal processes (asymmetric distributions).

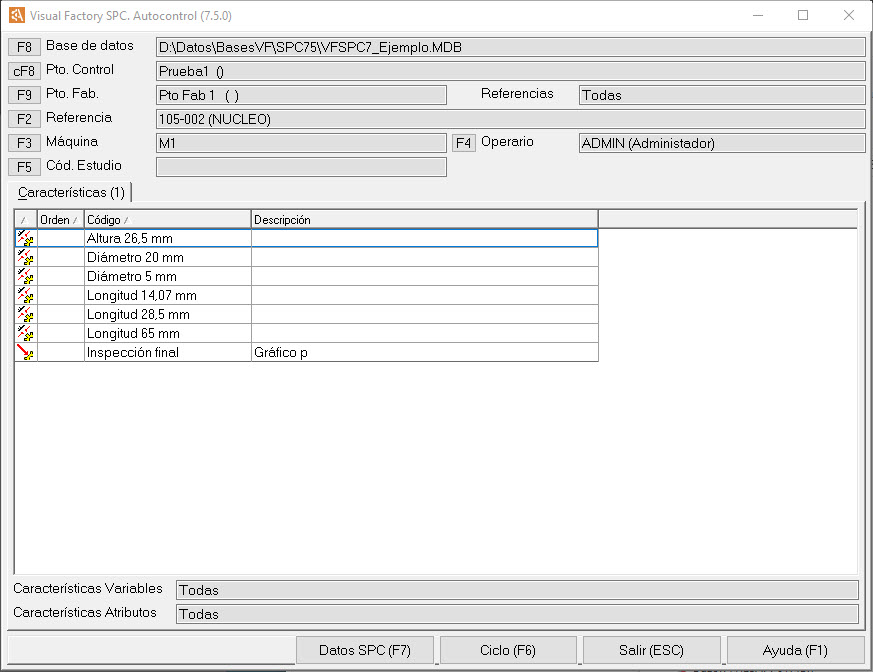

- Self-control module for use in production.

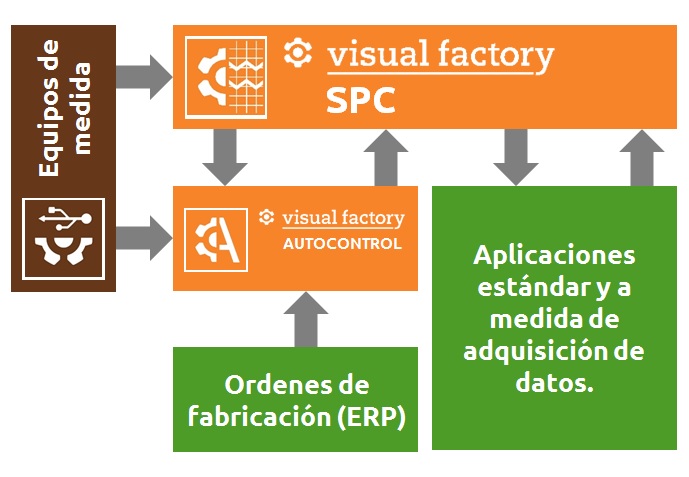

- Direct data input from measuring equipment connected to the computer.

- Data acquisition from three-dimensional and vision machines.

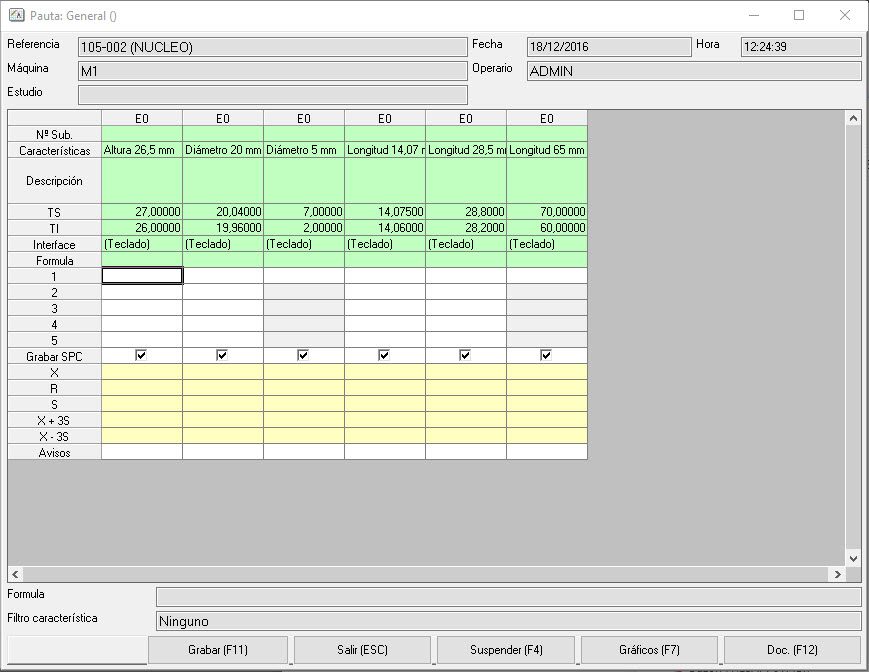

- Definition of guidelines for data entry.

- Integration with your company’s ERP to obtain information.

- Analysis of short and long term results.

- Wide variety of views and reports, which can be expanded by the user.

- Consultation of all the information in real time.

- Complies with the current IATF 16949 standard.

- Different options to suit your needs.

- Easy to configure and use.

- Supported by the technical support team

Visual Factory SPC is the application you need in your manufacturing lines.

Benefits of our Statistical Process Control software

Easy to install and use

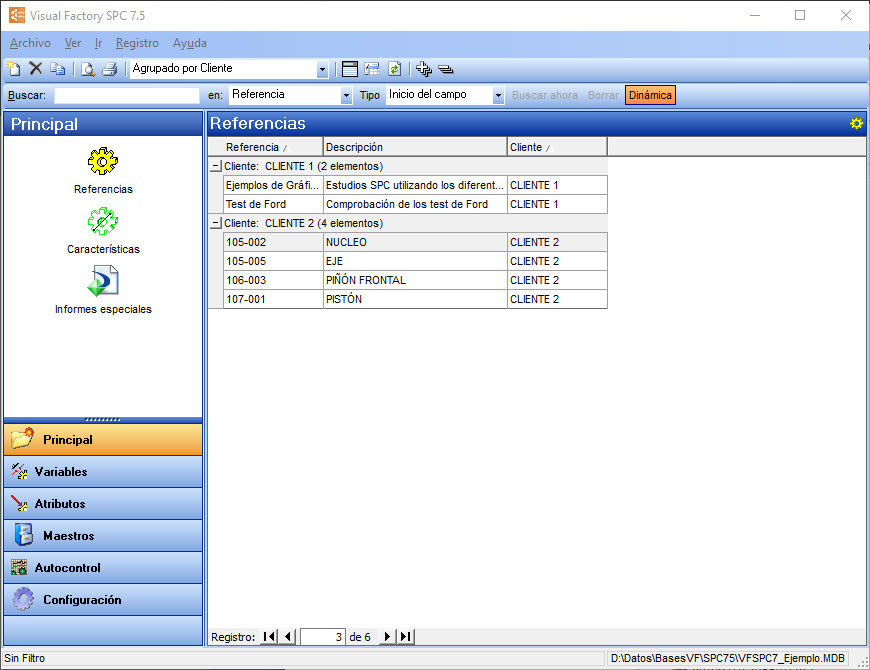

References used

Visual Factory SPC Editions

Visual Factory SPC SME

Basic edition designed for companies that do not require SPC management directly from the shop floor. It has all the computing power and reporting of the professional edition but without the self-monitoring options.

Visual Factory SPC Professional

Full edition designed so that data entry and process monitoring can be performed by the operator at self-monitoring stations located on the manufacturing lines.

Differences between options

| Functionality | SME | Profes. |

|---|---|---|

| Definition of references and characteristics | ||

| Process and machine capacity studies | ||

| Control charts, histogram and Henry line | ||

| Normal and non-normal distributions | ||

| Statistical analysis | ||

| Report and Label Designer | ||

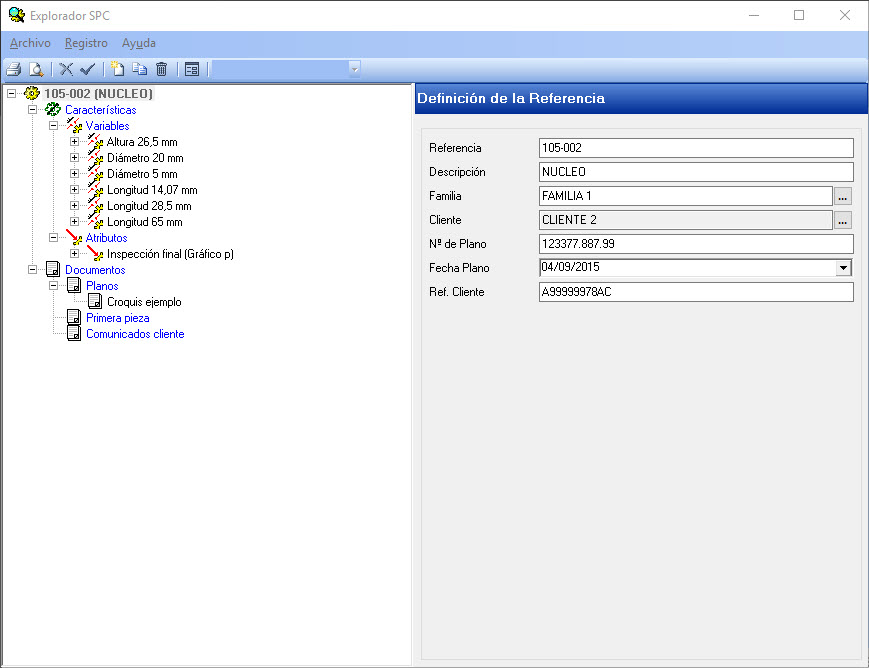

| Linked and/or attached files | ||

| Presentation of images in the reference configuration | ||

| Customizing public and private views to filter, group, sort, and format presented records | ||

| Viewing public and private views | ||

| Customizing fields and literals | ||

| Sending reports by e-mail and export to PDF | ||

| Access databases | ||

| Setting up special reports with Crytal Reports and MS Excel | ||

| Import between databases data | ||

| Export to MS Excel from views | ||

| Simultaneous access from several stations | ||

| MS SQL Server Databases | ||

| Direct reading from measuring equipment | ||

| Chart of evolution of capacity indices | ||

| Pareto of causes, corrective measures and decisions | ||

| Group of studies by variables | ||

| Pareto of defects accumulated over time | ||

| Defect evolution graph | ||

| Includes a Self-Control license |

Self-Monitoring Module

Allows the operator to record values for statistical control and directly monitor the quality of the manufacturing process.

Automatic Three-Dimensional Data Acquisition and Machine Vision Module (ATDDA)

Application for acquiring data directly from files generated from the measurement application of a 3D or vision machine.

Custom applications for data acquisition.

We develop custom applications that adapt to the client’s data capture and import needs.